All-Tex is committed to innovation and staying at the forefront of PVF technology, which is why we’re proud to partner with Transair by Parker.

Parker Hannifin is a pioneer in compressed air aluminum piping systems, and they’ve built on their history of continual innovation by manufacturing the largest range of diameters and products through their Transair piping system.

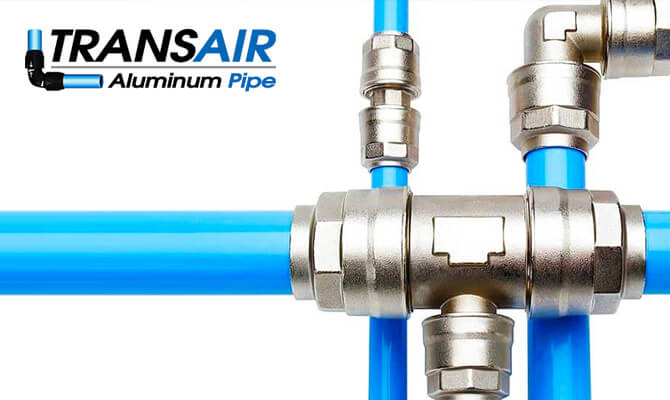

The lightweight components and quick-connect interlocking design of the Trainsair piping system allow for easy and immediate layout modifications with zero need to thread, solder or glue pipe. But Transair is the trusted brand of mechanical contractors for more reasons than just their 20 years of experience, over 750,000 installations and superior operational efficiency:

Low Cost. Labor accounts for only 20% of Transair installation costs, compared to the 50-80% of such costs associated with traditional steel or black iron compressed air piping. Energy costs are also reduced by Transair’s systems reducing pressure drops and eliminating leaks – improving efficiency while saving you money.

Equipment Longevity. Transair’s aluminum piping is designed to be corrosion-resistant. The piping is made from powder-coated aluminum, preventing corrosion and degradation over time, meaning less repairs and replacements.

Easy Integration. Transair’s compressed air piping integrates into existing copper and steel piping systems without compromising performance, which makes it perfect for upgrades or expansion projects.

Contact All-Tex today for the best selection of high-quality pipe, valves and fittings, including Transair by Parker. Our mission is to help you discover “value realized” in all your PVF projects.